The inner liner of the gas cylinder is made of high-quality 6061 aluminum alloy material and processed through processes such as stamping, stretching, heat treatment, CNC spinning and closing, and internal surface treatment.

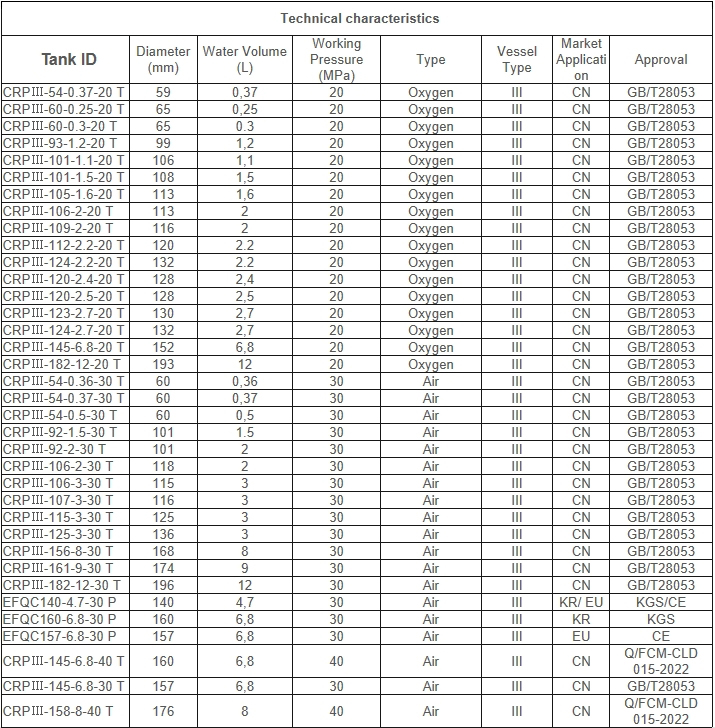

The inner liner has uniform wall thickness, small wall thickness difference, high accuracy and consistency in the shape of the shoulder and bottom. The inner surface is treated with anodizing, which has better corrosion resistance. The winding layer of the gas cylinder is made of imported high-quality carbon fiber, epoxy resin and other raw materials, processed through CNC winding, high-temperature curing and other processes. Compared to metal gas cylinders, they have better comprehensive performance, significantly increased working pressure, increased gas storage capacity, reduced weight by about 50%, and better corrosion resistance, insulation, shock absorption, and safety. It can provide effective respiratory protection when firefighters or rescue workers enter harsh environments such as smoke, toxic gas, dust, or oxygen deficiency, and is widely used in fields such as firefighting, mining, metallurgy, petroleum, electricity, medical, explosion-proof, and natural gas vehicles. In addition, our company can also produce aluminum lined carbon fiber fully wound gas cylinders of different specifications according to the different needs of users, with a volume of 0.3-500L; Outer diameter: 40mm-700mm; Our company has drafted the production standard GB28053 "Composite Gas Cylinders for Respirators" for this gas cylinder, and has obtained certifications such as BV, CE, PED, TPED, etc.